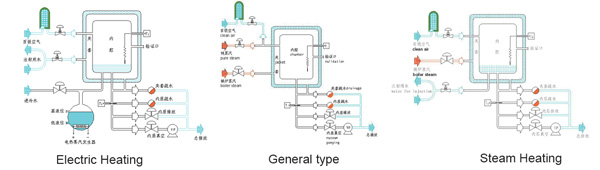

During the course of biotic pharmaceutics,there is a high requirement for asepsis and heat-free source,accordingly there is also an even higher requirement for sterilezer.According to GMP high standard and using high standard materials the following products in biotic pharmaceutics;Aluminum kegs for all kinds of antibiotic and their rubber covers and other high requirement usages.The structure of this series has double layers.During working,Pure steam is full of the inner layer, while the outer layer uses ordingary boiler steam.Therefore, it has two functions of vacuum exhaust and drying.During the course of biotic pharmaceutics,there is a high requirement for asepsis and heat-free source,accordingly there is also an even higher requirement for sterilezer.According to GMP high standard and using high standard materials the following products in biotic pharmaceutics;Aluminum kegs for all kinds of antibiotic and their rubber covers and other high requirement usages.The structure of this series has double layers.During working,Pure steam is full of the inner layer, while the outer layer uses ordingary boiler steam.Therefore, it has two functions of vacuum exhaust and drying.

■ Main Parameters & Utilities

|

Design pressure |

0.245Mpa |

Vacunm |

-0.095Mpa |

|

Working Pressure |

0.22Mpa |

Steam Source Pressure |

0.4-0.6Mpa |

|

Design Temperature |

139℃ |

Water Source Pressure |

0.1-0.3Mpa |

|

Working Temperature |

134℃ |

Compressed Air Pressure |

0.5-0.7Mpa |

|

Heat Equilibrium |

≤±1℃ |

Distiled Water |

0.1-0.2Mpa |

■ Structure&Capability&Characteristics

·The box is designed,produced and tested strictly according to the《 Steel Pressure Vessel》

·National patent door interlock

·National patent sealing technology of inner gas

·Reliable and stable micro-computer PLC+touch screen control,advanced function for recording,pringting and storing

·Elegant stainless steel decorate cover

·The heat preservation layer is made by polyurethane material and pearl rock wool

·The GMP confirmation access is fixed on the equipment

·The equipment has the function of creating steam by itself.

■ Size&Utilities

|

Specifications

Model |

Overall Dimensions

L*M*H(mm)

Single/Double Door |

Chamber Size

L*W*H(mm) |

Sream Consumpyion

(kg/cycle) |

Power

(KW) |

Water Consmption

(kg/cycle)

|

Distilled Water

(kg/cycle) |

|

|

CG-0.2 |

895*1220*1720 |

760*600*600 |

40 |

1.5 |

150 |

8 |

650 |

|

CG-0.3 |

1195*1220*1720 |

1000*600*600 |

55 |

1.5 |

180 |

12 |

760 |

|

CG-0.6 |

1245*1300*1880 |

1050*680*850 |

75 |

2.0 |

200 |

20 |

1100 |

|

CG-0.8 |

1595*1300*1880 |

1400*680*850 |

85 |

3.0 |

250 |

32 |

1300 |

|

CG-1.2 |

1695*1370*1960 |

1500*750*1100 |

100 |

3.0 |

300 |

40 |

1900 |

|

CG-2.5 |

3195*1370*1960 |

3000*750*1100 |

180 |

4.5 |

500 |

70 |

2800 |

|

CG-5.0 |

3635*1800*2200 |

3400*1000*1500 |

300 |

7.5 |

700 |

130 |

4500 |